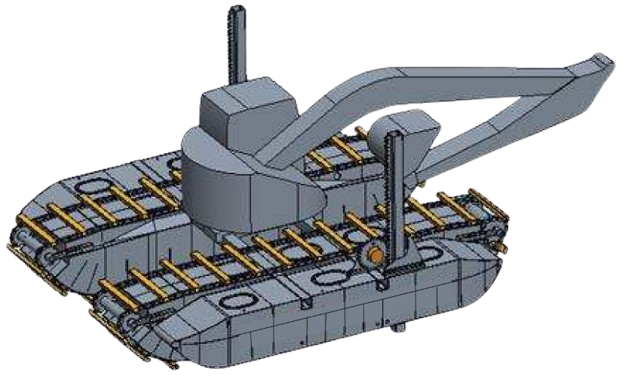

Tracked pontoon undercarriage systems that enable excavators to operate in shallow water and soft ground where standard equipment cannot work.

Typical operating environments

– shallow water zones and tidal areas

– soft seabeds and riverbanks

– marshland and peat soils

– dredging and reclamation sites

– transitional land–water environments

No amphibious tracked pontoons match your load capacity range requirements.

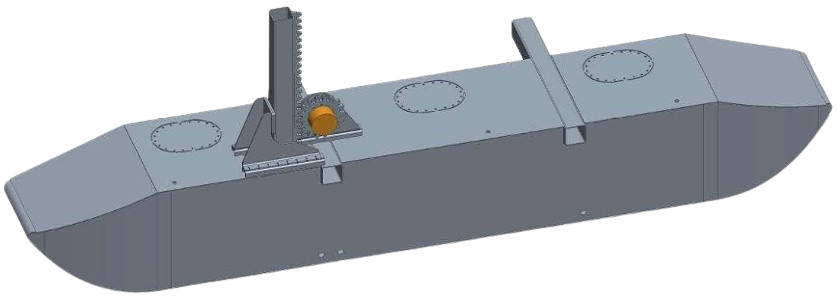

Auxiliary Pontoons (Sponsons)

Auxiliary Pontoons (Sponsons)

For projects where excavator mobility is not required, machines can often be operated from steel pontoons or floating work platforms instead. This can be a more cost-effective solution for stationary or semi-stationary marine operations.

Explore Steel PontoonsAmphibious tracked undercarriages are also commonly referred to as amphibious tracked pontoons, pontoon undercarriages, amphibious excavator pontoons, floating crawler bases, or amphibious track systems. Terminology varies by region and industry, but the underlying function remains the same.

Each undercarriage is designed for specific excavator weight classes and mounting points. We'll confirm compatibility with your machine model and, if needed, adapt the interface to ensure safe and stable installation.

They are designed for operation in soft, swampy, and shallow-water environments where standard tracked equipment cannot work. Depending on the model, they can handle varying depths and soil types typical of dredging, reclamation, or environmental projects.

Yes. The units can be disassembled into pontoons and track frames for transport by truck or container. Assembly on site is straightforward, allowing fast relocation between jobs.

Lead times depend on the specific model and current production schedule. Some components are already available, and we plan production to meet your deadlines. We'll confirm an indicative delivery timeframe when you request a quote.

We normally deliver ready-assembled units by road or sea, but can adapt logistics if the destination requires another method. Each project has its own routing and constraints - the main point is that we'll find the most practical and cost-effective delivery solution and handle the details with you directly.

Yes. We offer ongoing support for maintenance, repairs, and spare components. Our team stays available after delivery to help with any operational questions or parts replacement, ensuring the equipment stays in service with minimal downtime.

To recommend the right pontoon configuration, we typically need:

• required load capacity

• target deck size or working area

• equipment type and weight (if machinery will be installed)

• brief description of how the platform will be used

• project location and delivery region

Based on this, we assess buoyancy, stability, deck strength, and overall feasibility — and then propose a suitable solution.

Contact our marine experts to discuss your project requirements and get a detailed quote for your vessel needs.

Our engineers respond within one business day

Related models and alternative solutions: